Case study 1

„TOOL LIFE 26M PER ACTIVE HOB TOOTH, 17’000 PARTS PRODUCED PER RESHARPENING"

Application

Car Gear Box ManufacturingCustomer request

Reduction of cost per part maintaining the same cycle time, dry finish hobbing before heat treatment, in DIN quality class 7Suggested solution by Schnyder

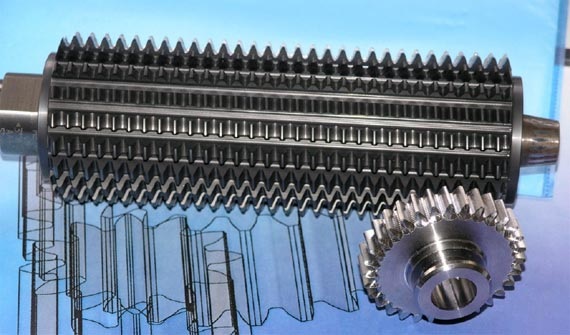

Replacement of PM steel hob with solid carbide nanograin hob.Component / tool

Component / gear data

31 tooth spur gear, DP12 (M2.1167) – 20° PA, external Ø70.3mm, useful length 17mm, material 16MnCr5 with 630 N/mm2Hob specification

Shank type gear hob: Ø80 x 273/ 200 – shank Ø32/ SK30 - 19 gashes, Nanograin solid carbide (AAA) / 2 RHSCoating: Alcrona

Process

First cut: h 4.60mm in climb cutting vc 280 m/min. / fa 1.80 mm/RSecond cut: h 5.125mm conventianal cutting vc 400 m/min. / fa 1.20 mm/R

chip thickness ca. 0.10- 0.13mm

Hobbing machine

Pfauter P210 CNCResult

# of parts produced per resharpening: 17‘000 pcs (!) # of resharpenings: 25

Total cutting length: 151‘000 m

Chip volume: 6‘300 mm3/piece

Total # of hob teeth: 285

# of active hob teeth: 238

Tool life: 26 m / active hob tooth

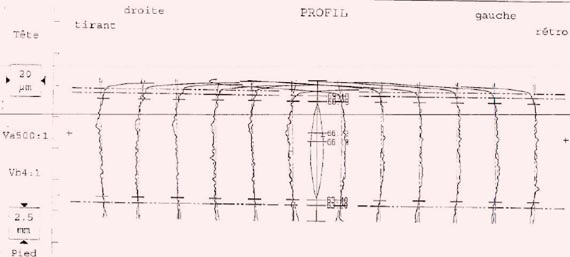

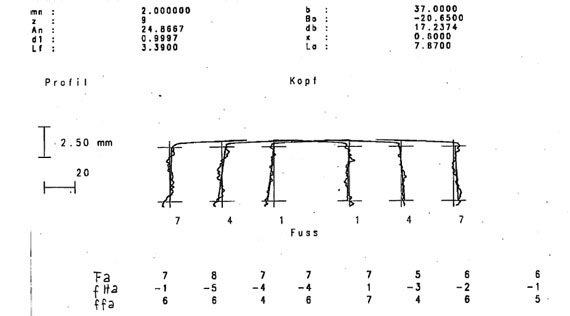

Achieved gear quality with new hob

Achieved gear quality after 13'000 parts (wear of 0.05mm)

Customer benefit

Tool life of PM steel hob: 2'000 parts per resharpening.Achieved tool life with Schnyder solid carbide hob: 17'000 parts per resharpening.

Benefit:

lower cost per part

lower cost per part longer tool change interval

longer tool change interval

Case study 2

„TOOL LIFE 26M PER ACTIVE HOB TOOTH, 17’000 PARTS PRODUCED PER RESHARPENING“

Application

Car Steering System ManufacturingCustomer request

Reduction of cost per part maintaining the same cycle time, dry finish hobbing before heat treatment, in DIN quality class 7Suggested solution by Schnyder

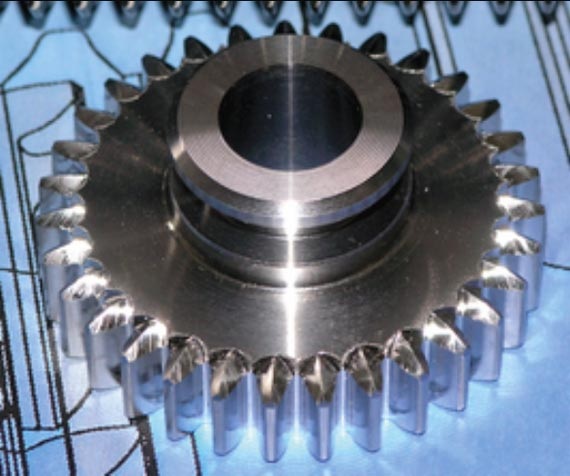

Solid carbide shank hob type PERFECT CUT®Component / tool

Component / gear data

9 tooth helical pinion, Mn 2.00 – 25° PA, external Ø24mm, useful length 45mm, material 16MnCr5 with 630 N/mm2Hob specification

Shank type gear hob: Ø50 x 233/ 153 – shank Ø22 (2x) - 15 gashes, Nanograin solid carbide (AAA) / 1 LHSCoating: Alcrona

Process

First cut: h 3.16mm; in climb cutting vc 375 m/min. / fa 1.50 mm/RSecond cut: h 3.46mm; conventianal cutting vc 400 m/min. / fa 1.20 mm/R

chip thickness ca. 0.16mm

Hobbing machine

Gleason Pfauter P60 CNCResult

# of parts produced per resharpening: 44‘000 pcs (!)# of resharpenings: 24

Total cutting length: 440‘000 m

Chip volume: 5'042 mm3/piece

Total # of hob teeth: 349

# of active hob teeth: 296

Tool life: 65 m / active hob tooth

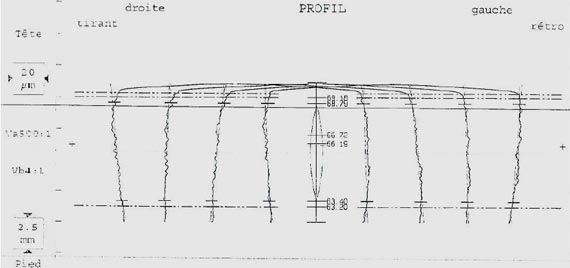

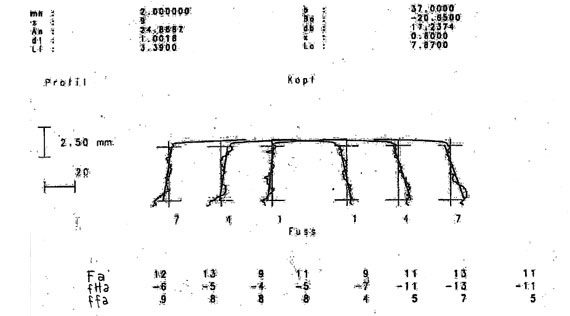

Achieved gear quality with new hob

Achieved gear quality after 44'000 parts (wear of 0.1mm)

Customer benefit

Tool life of standard hob: 12'000 parts per resharpening.Achieved tool life with Schnyder PERFECuT® hob: 44'000 parts per resharpening.

Benefit:

lower cost per part

lower cost per part longer tool change interval

longer tool change interval